Mooring Tail

High Performance PP & PET Mixed Mooring Tail,made by 53% polyester and 47% polypropylene composite yarns, the standard length is 11m and 22m,come with two protected and spliced eyes of 1m or 1.8 m or 2m respectively. Has a close strength and elongation when wet and dry, easy to handle、flexibility use and good abrasion resistance.

Category:

Product Introduction

Application: Widely used in Ship Mooring system, port towing.

High Performance PP & PET Mixed Mooring Tail,made by 53% polyester and 47% polypropylene composite yarns, the standard length is 11m and 22m,come with two protected and spliced eyes of 1m or 1.8 m or 2m respectively. Has a close strength and elongation when wet and dry, easy to handle、flexibility use and good abrasion resistance.

OCIMF recommends mooring tails with a MBL of 125~130% of ship design MBL.

★Specific Gravity : 1.14

★UV Resistance : Good

★Abrasion Resistance : Very Good

★Chemical Resistance : Good

★Melting Point : Approx.165 ℃/265 ℃

★Construction : 8 strand plaited

★Warer Absorption : 79.6%

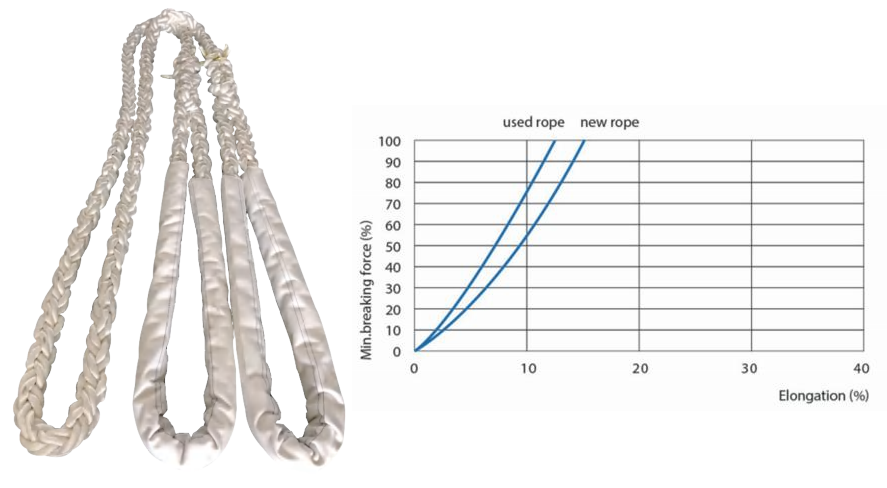

★Elongation : 12.5~17%

Application: Widely used in Ship Mooring system, port towing.

|

Specification |

Mixed Polyester |

||

|

Diameter |

Circumference |

Linear density |

Breaking strength |

|

48 |

6 |

1426 |

498 |

|

56 |

7 |

1933 |

657 |

|

60 |

7-1/2 |

2165 |

747 |

|

62 |

7-3/4 |

2303 |

792 |

|

64 |

8 |

2441 |

837 |

|

68 |

8-1/2 |

2754 |

943 |

|

72 |

9 |

3067 |

1049 |

|

76 |

9-1/2 |

3418 |

1160 |

|

80 |

10 |

3769 |

1271 |

|

84 |

10-1/2 |

4288 |

1399 |

|

88 |

11 |

4806 |

1527 |

|

96 |

12 |

5400 |

1822 |

Those 3 strand ropes can made by Nylon / PP Monofilament / PP Multifilament / Polyester / PE raw material to produce different kinds of ropes. Can widely used in ocean fishing, deep sea aquaculture, port, industrial,civil and so on.

|

Specification |

Polyamide(Nylon) |

Polypropylene monofilament |

Polypropylene Multifilament |

Polyester |

|||||

|

Diameter |

Circumference |

Linear density |

Breaking strength |

Linear density |

Breaking strength |

Linear density |

Breaking strength |

Linear density |

Breaking strength |

|

4 |

1/2 |

10.5 |

2.94 |

7.23 |

2.78 |

7.6 |

2.9 |

12.3 |

3 |

|

6 |

3/4 |

22.5 |

7.84 |

16.3 |

5.92 |

17 |

6.12 |

27.3 |

6.72 |

|

8 |

1 |

40.0 |

13.7 |

28.9 |

10.1 |

30 |

10.5 |

48.5 |

11.6 |

|

10 |

1-1/4 |

61.7 |

20.6 |

45.2 |

15.4 |

47 |

16.1 |

75.6 |

17.5 |

|

12 |

1-1/2 |

88.8 |

29.4 |

65.1 |

21.6 |

68 |

22.2 |

109 |

24.7 |

|

16 |

2 |

158 |

51.9 |

116 |

37.0 |

122 |

38.9 |

194 |

42.1 |

|

18 |

2-1/4 |

200 |

65.7 |

146 |

46.2 |

153 |

48.2 |

246 |

52.5 |

|

20 |

2-1/2 |

247 |

81.3 |

181 |

56.1 |

190 |

58.3 |

303 |

64.0 |

|

24 |

3 |

355 |

117.6 |

260 |

78.8 |

270 |

80.2 |

437 |

89.6 |

|

26 |

3-1/4 |

417 |

137.2 |

306 |

91.5 |

320 |

93.2 |

512 |

104 |

|

28 |

3-1/2 |

484 |

157 |

354 |

105 |

370 |

111 |

594 |

119 |

|

30 |

3-3/4 |

555 |

176 |

407 |

119 |

430 |

124 |

682 |

136 |

|

32 |

4 |

632 |

196 |

463 |

134 |

480 |

137 |

776 |

154 |

|

36 |

4-1/2 |

800 |

245 |

586 |

167 |

615 |

182 |

982 |

191 |

|

40 |

5 |

987 |

294 |

723 |

204 |

760 |

208 |

1210 |

233 |

|

44 |

5-1/2 |

1190 |

353 |

875 |

243 |

925 |

253 |

1470 |

278 |

|

48 |

6 |

1420 |

412 |

1040 |

286 |

1090 |

299 |

1750 |

327 |

|

52 |

6-1/2 |

1670 |

480 |

1220 |

332 |

1280 |

352 |

2050 |

379 |

|

56 |

7 |

1930 |

549 |

1420 |

381 |

1490 |

398 |

2380 |

463 |

|

64 |

8 |

2530 |

706 |

1850 |

488 |

1940 |

510 |

3100 |

558 |

|

72 |

9 |

3200 |

883 |

2340 |

608 |

2460 |

623 |

3930 |

692 |

|

80 |

10 |

3950 |

1084 |

2890 |

740 |

3040 |

782 |

4850 |

850 |

|

88 |

11 |

4780 |

1314 |

3500 |

887 |

3680 |

901 |

5870 |

1010 |

|

96 |

12 |

5690 |

1540 |

4170 |

1040 |

4380 |

1098 |

6990 |

1190 |

Keywords:

Mooring Tail

Related Products

Product Message

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible