Management and Maintenance of Bulk Carrier Mooring Rope

Release time:

2026-01-23

The management and maintenance of Bulk Carrier Mooring Ropes is not only about extending their lifespan, but also a crucial step in ensuring safe berthing and reducing accidents

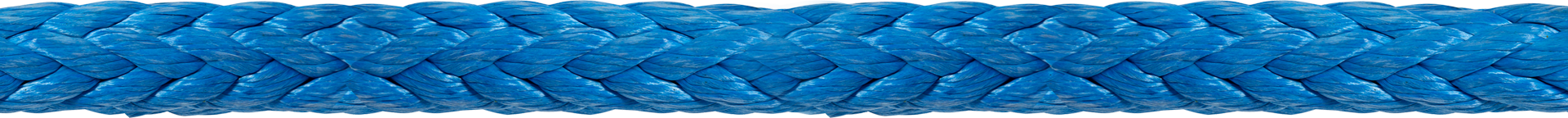

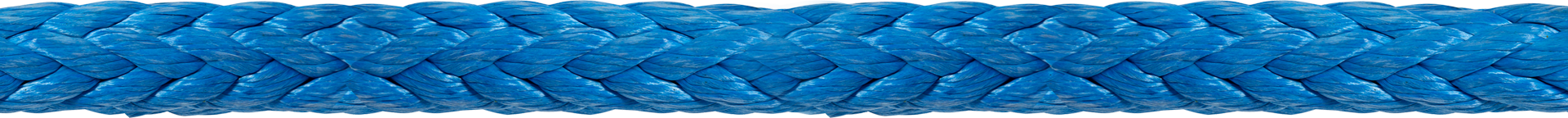

In modern shipping, the safety and efficiency of bulk carriers rely heavily on a series of crucial pieces of equipment, one of which is the mooring rope. Mooring ropes are used to stabilize the vessel during berthing, anchoring, and operations at sea. Proper management and maintenance not only extend the lifespan of the mooring rope but also ensure the safety of the vessel. The following are methods for managing and maintaining a bulk carrier mooring rope:

1. Regular Inspection and Assessment

- Mooring ropes are subject to varying degrees of wear, corrosion, or damage during use, making regular inspections essential. Inspections should include:

- Surface Wear: Inspect the rope's surface for obvious wear or breakage, especially in areas under heavy stress.

- Core Inspection: The rope's core is the central component that bears the tensile force. A break or compression of the core can lead to mooring rope failure.

- Knots and Folds: Check for knots, excessive bending, or folds in the rope, as these can affect its load-bearing capacity.

2. Cleaning and Drying

Mooring lines easily absorb seawater, dirt, and other impurities during use, affecting their strength and extending their service life. Maintenance methods include:

- Cleaning: Rinse the rope with clean water, especially the parts exposed to seawater, to remove salt, sand, and other impurities.

- Drying: After washing, allow the Bulk Carrier Mooring Rope to air dry naturally in a well-ventilated area to prevent mold or rot caused by moisture.

3. Avoid Overloading and Excessive Extension

Each mooring line has its rated working tensile strength, and the specified load capacity must be followed during use. Avoid excessive tension or overloading during mooring. Overloading not only reduces the service life of the mooring line but may also cause breakage.

4. Proper Storage

When not in use, mooring lines should be stored in a dry, cool place. Avoid exposing the rope to direct sunlight, as ultraviolet rays accelerate its aging process. Avoid over-tightening the rope during storage; ensure it is naturally relaxed and not excessively compressed.

5. Regular Replacement

While regular inspection and maintenance can extend the lifespan of mooring lines, their performance gradually declines over time. Shipping companies should regularly replace aged or severely damaged mooring lines based on usage frequency and line condition. Generally, mooring lines should be replaced every 3-5 years, but the specific interval should be determined based on the vessel's operating environment and the line's condition.

The management and maintenance of Bulk Carrier Mooring Ropes is not only about extending their lifespan but also a crucial step in ensuring safe berthing and reducing accidents. Regular inspection, cleaning, proper storage, and timely replacement can effectively prevent safety accidents caused by mooring line problems, ensuring the smooth operation of shipping activities.

Recent information