What Makes Polypropylene Rope Production Unique

Release time:

2025-10-10

The production process of polypropylene rope, through precise polymerization, drawing, braiding, and post-processing, imparts exceptional strength, flexibility, and durability

1. Precision Polymerization: Laying the Foundation for High-Quality Rope

The production process for polypropylene rope begins with polymerization. First, propylene monomers are polymerized under high temperature and pressure to create polypropylene resin. This resin, the primary raw material for the rope, boasts a precisely controlled molecular chain structure, resulting in the rope's superior strength, elasticity, and durability. During the polymerization process, temperature, pressure, and catalyst selection are rigorously controlled to ensure consistent resin quality, laying a solid foundation for subsequent rope weaving.

2. Efficient Wire Drawing and Braiding: Creating a Strong Structure

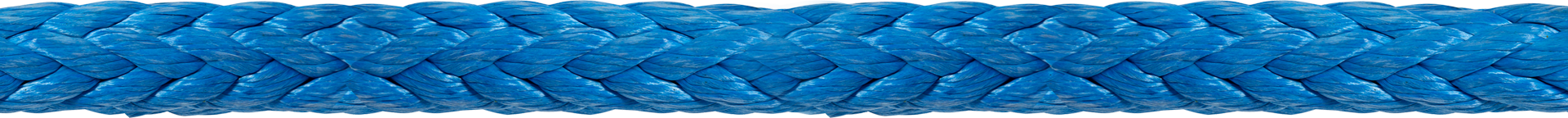

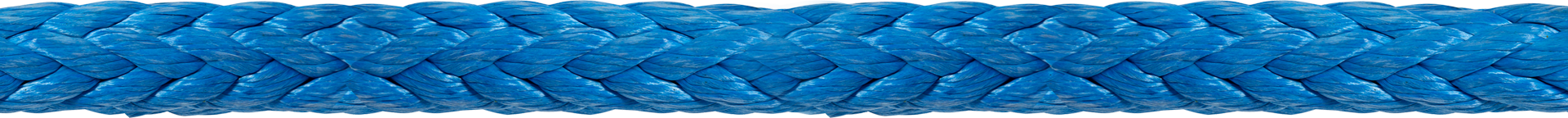

Next, the polypropylene resin is drawn into filaments through an efficient extrusion process. This process utilizes high-temperature heating and precise equipment control to ensure the uniformity and toughness of each fiber. These polypropylene fibers are then braided, using advanced automated braiding machines to interweave multiple strands, enhancing the rope's tensile strength and flexibility. The meticulous braiding process in this process determines the rope's lifespan and its performance in challenging environments.

3. High-Standard Post-Processing: Ensures Stable Quality and Durability

The final step in production is post-processing, which includes high-temperature shaping, UV-resistant coating, and antioxidant treatment. High-temperature shaping stabilizes the polypropylene rope's shape, preventing deformation from stretching or uneven stress during long-term use. Furthermore, the UV-resistant coating ensures the rope maintains excellent performance even in strong sunlight, making it particularly suitable for outdoor work and locations exposed to prolonged sunlight. The antioxidant treatment ensures the rope's resistance to moisture, chemicals, and corrosive environments, extending its service life.

Overall, the production process of polypropylene rope, through precise polymerization, drawing, braiding, and post-processing, imparts exceptional strength, flexibility, and durability. Exquisite craftsmanship and strict quality control at every stage ensure its outstanding performance in a variety of challenging environments, making it a reliable choice for a wide range of industries.

Recent information