Advantages of polymer cables

Release time:

2020-02-27

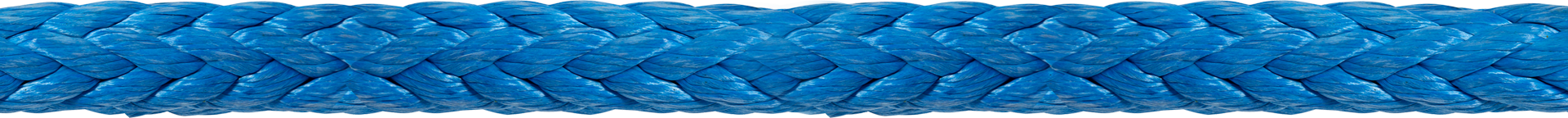

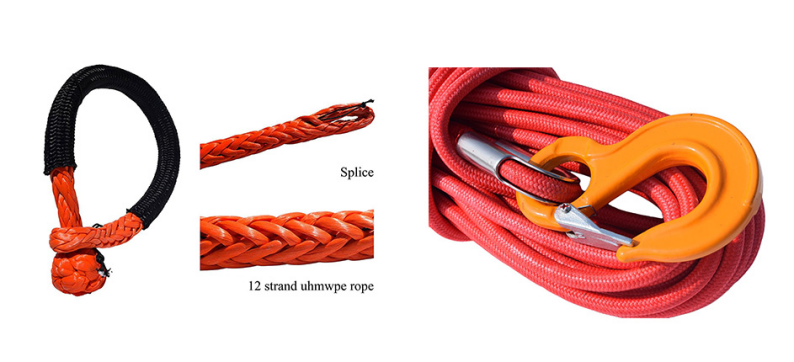

Yasheng polymer cables are made of ultra-high molecular polyethylene. Yasheng's proprietary design and high-tech production process are used to produce the best ultra-high grade polyethylene cables in China. Under the same diameter, it is stronger than steel wire ropes and weighs 1/8 of steel wire ropes. Under the same weight, polymer ropes are 15 times higher than steel wire ropes. The strength is the highest in the world, about 1.5 times higher than steel wire ropes of the same diameter; Yasheng polymer cables are made of our unique dipping process and unique drying and heat treatment processes to enable the rope to achieve its best performance and anti-wear performance. The advantages are: floating, small diameter, high breaking force, easy and simple operation, low elongation of 3.5% ~ 4%, and a service life of 3~5 times that of other cables. Excellent durability, resistance to seawater, chemicals, UV radiation and repeated temperature differences, and unchanged quality during use; easy and fast operation, safe use, and short operation time.

Advantages of polymer cables

Yasheng polymer cables are made of ultra-high molecular polyethylene. Yasheng's proprietary design and high-tech production process are used to produce the best ultra-high grade polyethylene cables in China. Under the same diameter, it is stronger than steel wire ropes and weighs 1/8 of steel wire ropes. Under the same weight, polymer ropes are 15 times higher than steel wire ropes. The strength is the highest in the world, about 1.5 times higher than steel wire ropes of the same diameter; Yasheng polymer cables are made of our unique dipping process and unique drying and heat treatment processes to enable the rope to achieve its best performance and anti-wear performance. The advantages are: floating, small diameter, high breaking force, easy and simple operation, low elongation of 3.5% ~ 4%, and a service life of 3~5 times that of other cables. Excellent durability, resistance to seawater, chemicals, UV radiation and repeated temperature differences, and unchanged quality during use; easy and fast operation, safe use, and short operation time.

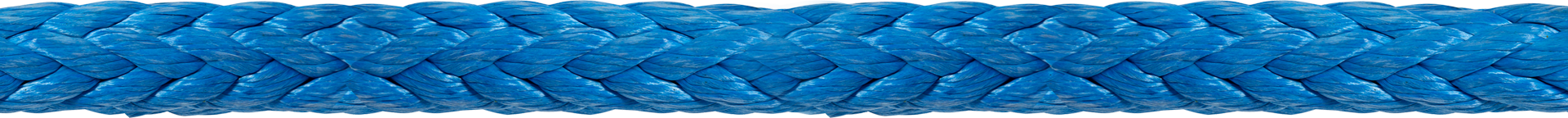

The high molecular polyethylene cable includes a rope core made of high molecular polyethylene monofilaments and a plurality of main rope strands twisted around the rope core. The main rope strands are composed of a strand core and six or twelve secondary rope strands twisted around the strand core. The strand core is made of high molecular polyethylene monofilaments and the secondary rope strands are made of chemical fiber monofilaments. The main rope strands are further increased by arranging strands made of metal monofilaments, so the cross-sectional radius of the strands as the rope core can be greatly reduced (because the setting of the strand core shares the cross-sectional radius requirement of the rope core), which in turn increases the durability of the original new sea rope and ensures that it can be used normally when winding or dragging. At the same time, the setting of the strand core increases the strength of each rope strand. While ensuring the use strength, the durability and service life are improved.

Magical properties of tensile fatigue

Due to the extremely high molecular weight of UHMWPE, the draft ratio when making fibers from it is far from the optimal theoretical value. Under repeated tensile forces, the breaking strength of ropes made of this fiber will gradually increase with the increase of the fiber draft ratio. This is a magical property that ropes made of other materials do not have. According to laboratory and actual use tests, UHMWPE ropes have excellent tensile fatigue properties.

Wear and bending resistance

The surface of high molecular polyethylene fiber is smooth and has a low friction coefficient, so it has excellent axial wear resistance.

Low temperature resistance

It can be used in extreme low temperature environments, and can withstand extreme high and low temperatures in long-term atmospheric environments and outdoor use; its fiber strength is well maintained, and the softness does not change much.

Recent information