What is ultra high molecular weight polyethylene fiber

Release time:

2020-02-28

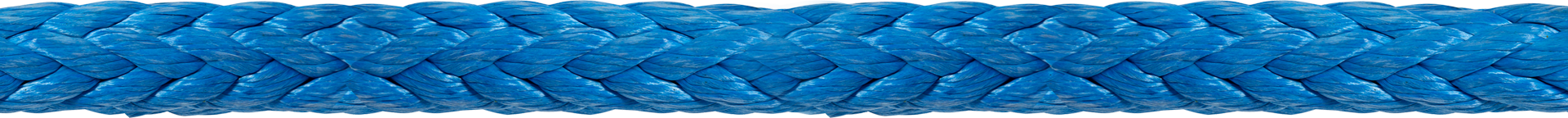

Ultra-high molecular weight polyethylene fiber (English full name: Ultra High Molecular Weight Polyethylene Fiber, referred to as UHMWPE), also known as high-strength high-modulus polyethylene fiber, is the fiber with the highest specific strength and specific modulus in the world. It is a fiber spun from polyethylene with a molecular weight of 1 million to 5 million.

What is ultra-high molecular weight polyethylene fiber?

Ultra-high molecular weight polyethylene fiber (English full name: Ultra High Molecular Weight Polyethylene Fiber, referred to as UHMWPE), also known as high-strength high-modulus polyethylene fiber, is the fiber with the highest specific strength and specific modulus in the world. It is a fiber spun from polyethylene with a molecular weight of 1 million to 5 million.

Three major features

Strong durability

Light-resistant, aging-resistant, corrosion-resistant, wear-resistant, acid-resistant, alkali-resistant, cold-resistant, corrosion-resistant, easy to store, smooth surface, not easy to lint, long service life.

Lightweight and high quality

Made of ultra-high molecular weight polyethylene fiber, it is soft to the touch, light to carry, easy to use, and in case of breakage, it can be braided and knotted for continued use, unlike steel cables which are difficult to continue using once they break. Because the ultra-high molecular weight polyethylene fiber rope is small in size and light in weight, in order to ensure the cleanliness of the rope, it does not need to be wrapped around the winch when not in use.

Strong safety

High safety factor, its low stretch performance makes it more sensitive: low elongation and low weight combined make it easy to operate and more suitable for accurate operation of ships, especially in distress and critical moments.

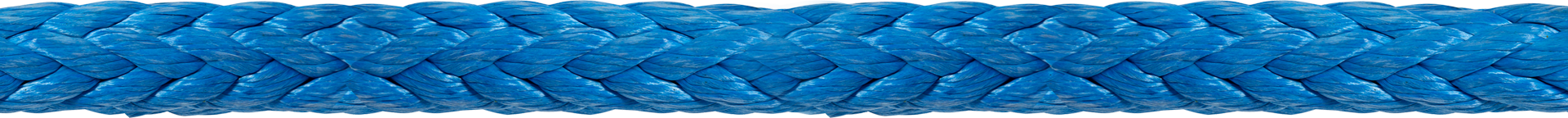

Special properties:

1. High specific strength and high specific modulus. The specific strength is more than ten times that of steel wire with the same cross-section, and the specific modulus is second only to special carbon fiber.

2. The fiber density is low, the density is 0.97-0.98g/cm, and it can float on the water.

3. The elongation at break is low, the work at break is large, and it has a strong ability to absorb energy, so it has outstanding impact resistance and cutting resistance.

4. It is resistant to ultraviolet radiation, neutrons and gamma rays, has high specific energy absorption, low dielectric constant, and high electromagnetic wave transmittance.

5. It is resistant to chemical corrosion, wear resistance, and has a long flex life.

Physical properties:

Density: 0.97~0.98g/cm. It is lower than the density of water and can float on the water.

Strength: 2.8~4N/tex.

Modulus: 91~140N/tex.

Elongation: 3.5%~3.7%.

The impact absorption energy is nearly twice as high as that of para-aramid fiber, with good wear resistance and low friction coefficient.

HMWPE ropes are considered to be the most suitable ropes for marine and industrial applications. In addition, they are also suitable for performance yachts, aquaculture, commercial fishing, mountaineering, etc.

HMWPE ropes float on the water and have a high safety factor. Its low tensile properties make it more sensitive: the combination of low elongation and low weight makes it easy to operate and more suitable for accurate operation of ships, especially in distress and critical moments.

UHMWPE ropes are small in size (due to the small size used), so they are suitable for emergency situations and can be easily operated even by individuals.

UHMWPE cables have a high level of safety factor and meet the latest OCIMF safe mooring regulations.

Recent information