Splicing method of eyelet and loop of ultra-high molecular weight polyethylene fiber rope

Release time:

2020-02-28

A splicing method of eye loops of ultra-high molecular weight polyethylene fiber ropes, involving the field of rope nets, has a simple manufacturing process, convenient operation, a firm and durable splicing method, no need for special training, and a high strength retention rate. The eye loops produced can ensure that the strength of the ropes used is above 90%. It is more practical and can be directly used on slings, rings, pins, quick draws and other devices, greatly improving the efficiency of rope use and having a wider range of applications.

Splicing method of eye loops of ultra-high molecular weight polyethylene fiber ropes

A splicing method of eye loops of ultra-high molecular weight polyethylene fiber ropes, involving the field of rope nets, has a simple manufacturing process, convenient operation, a firm and durable splicing method, no need for special training, and a high strength retention rate. The eye loops produced can ensure that the strength of the ropes used is above 90%. It is more practical and can be directly used on slings, rings, pins, quick draws and other devices, greatly improving the efficiency of rope use and having a wider range of applications.

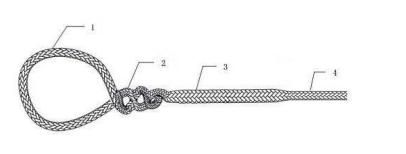

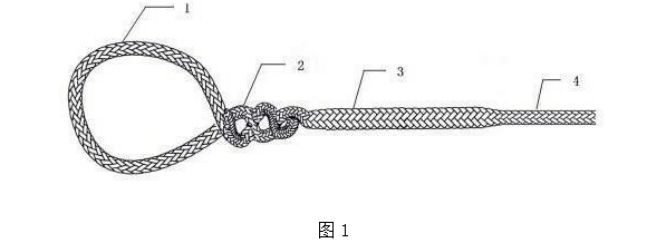

1. A method for splicing an eyelet loop of an ultra-high molecular weight polyethylene fiber rope, characterized in that the eyelet loop comprises an eyelet (1), a braid (2), an insert (3) and a main rope (4), wherein the eyelet (1) is connected to the main rope (4) through the braid (2) and the insert (3), and the specific splicing is achieved by the following steps:

Cut one end of the rope into a cone and wrap it with tape to ensure that the rope end is smooth and free of burrs;

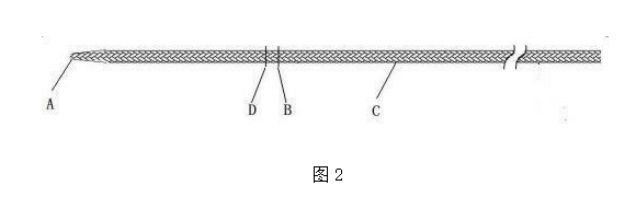

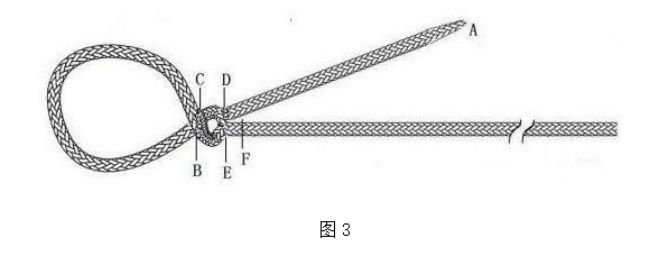

Starting from the conical end of the rope, mark A, B, and C respectively, as shown in Figure 2, wherein the AB segment is used to form the braid (2) and the insert (3), and in the splicing process, points B and C coincide as the eyelet (1), and the longer end extending from C is the main rope (4); starting from the B end, measure 1/3 of the pitch length in the direction of the rope end A and mark it as D, insert the main rope (4) from D and then withdraw it until the mark B and the mark C are aligned. Overlap, at this time, the point on the main rope (4) that overlaps with mark D is marked as E, as shown in Figure 3; at point E, measure 1/3 of the pitch length along the direction of the main rope (4) and mark it as F, insert end A from point F and pull it out; at point F, measure 1/3 of the pitch length along the direction of the main rope (4) and mark it as G, as shown in Figure 4, insert the remaining end A as the insert (3) into the main rope (4), arrange it, and form an eye ring rope loop, as shown in Figure 4, and sew the insert (3) with sewing thread according to specific needs.

2. The method for splicing an eye ring rope loop of an ultra-high molecular weight polyethylene fiber rope according to 1, characterized in that the length of the rope mark AB section is set to 40-50 times the rope diameter.

3. The method for splicing eye loops of ultra-high molecular weight polyethylene fiber ropes according to 1 is characterized in that the throat angle formed between the eye loop (1) and the main rope (4) is set to within 30°.

Twelve-braided braided ropes represented by ultra-high molecular weight polyethylene fiber ropes often have the characteristics of high strength and low elongation. Various splicing methods are inevitably used in the process of strength testing and rope use. According to research, a good splicing method should not reduce the strength of a rope by more than 10%. When the rope is knotted during use, the strength utilization rate of the rope will be less than 50%, so it is necessary to splice the rope in the extension direction of the rope strands.

In order to solve the above-mentioned technical problems, this paper provides a method for splicing eye loops of ultra-high molecular weight polyethylene fiber ropes. The eye loops formed can be used to connect quick-hanging, pins, slings and other devices, and are suitable for outdoor operations, lifting slings, leisure and entertainment, mine production and other fields. The splicing method has a short operation time and significantly improves the efficiency and strength of the rope.

Technical solution:

A method for splicing an eye loop of an ultra-high molecular weight polyethylene fiber rope, wherein the eye loop comprises an eye loop, a braid, a core and a main rope, wherein the eye loop is connected to the main rope through the braid and the core, and the specific splicing is achieved through the following steps:

1) Cut the two ends of the rope into a cone and wrap them with tape to ensure that the rope ends are smooth and free of burrs;

2) Mark A, B, and C from one end of the rope, wherein the AB segment is used to form the braid and the core, and during the splicing process, the two points B and C coincide, as the eye loop, and the longer end extending from C is the main rope;

3) Measure 1/3 of the pitch length from the B end in the direction of the rope end A and mark it as D, insert the main rope from D and then pull it out until the mark B coincides with the mark C, and the point on the main rope that coincides with the mark D is marked as E.

4) At point E, measure 1/3 of the pitch length along the main rope direction and mark it as F, insert and pull out the A end from F. [0006] 5) At point F, measure 1/3 of the pitch length along the main rope direction and mark it as G, insert the remaining A end as the insert into the main rope, arrange it, and form an eye loop.

The length of the rope marked AB section is set to 40-50 times the rope diameter.

The throat angle formed between the eye and the main rope is set to within 30°.

The eye loop rope splicing method provided in this article has a simple manufacturing process, convenient operation, a firm and durable splicing method, no special training is required, and has a high strength retention rate. The manufactured eye loop rope can ensure that the strength of the rope used is above 90%, and it is more practical. It can be directly used on slings, rings, pins, quick hangers and other devices, greatly improving the use efficiency of the rope and having a wider application field.

Drawings

Figure 1 is a schematic diagram of the structure;

Figures 2-4 are the steps for splicing the eye loop.

Specific implementation method:

Combined with the accompanying drawings and specific embodiments, the detailed description is as follows:

As shown in Figures 1-4, the eyelet rope loop of the ultra-high molecular weight polyethylene fiber rope has an eyelet 1, a braid 2, a core 3 and a main rope 4. The eyelet is connected to the main rope through the braid and the core. The specific splicing is achieved by the following steps:

1) Cut the two ends of the rope into a cone and wrap them with tape to ensure that the rope ends are smooth and free of burrs;

2) Mark A, B, and C from one end of the rope, where the AB segment is used to form the braid 2 and the core 3. During the splicing process, the two points B and C coincide as the eyelet 1, and the longer end extending from C is the main rope 4;

3) Measure 1/3 of the pitch length in the direction of rope end A from end B and mark it as D. Insert the main rope 4 from D and then pull it out until the mark B and mark C are aligned. Overlap, and the point on the main rope 4 that overlaps with mark D is marked as E.

4) At point E, measure 1/3 of the pitch length along the direction of the main rope 4 and mark it as F, insert and pull out end A from point F. [0013] 5) At point F, measure 1/3 of the pitch length along the direction of the main rope 4 and mark it as G, insert the remaining end A as the insert 3 into the main rope 4, arrange it, form an eye loop rope loop, and sew the insert 3 with sewing thread according to specific needs.

The length of the rope mark AB section is set to 40-50 times the rope diameter.

The throat angle formed between the eye loop 1 and the main rope 4 is set to within 30°.

Example 1:

Use the eye-ring pin method to conduct a strength test on a 12-strand ultra-high molecular weight polyethylene rope with a diameter of 4mm. The specific operation steps are as follows:

Step 1, cut 1.2m of the test rope with a diameter of 4mm, cut the two ends of the test rope into a cone and wrap it tightly with tape;

Step 2, starting from one end of the test rope, mark them as A, B, and C respectively, where the spacing between A and B is 50 times the diameter of the test rope, that is, 500px, and the spacing between B and C is the length of the rope eye ring. The pin diameter used in the strength test is 20mm, and the length of the eye ring spacing BC is 375px, so that the throat angle formed is within 30°;

Step 3, starting from the B end, measure 1/3 of the pitch length in the direction of the rope end A and mark it as D, insert the main rope part from D and then pull it out until the mark B coincides with the mark C. At this time, the main rope is aligned with the mark The point where D overlaps is marked as E. At point E, measure 1/3 of the pitch length along the main rope direction and mark it as F. Insert and pull out end A from point F. At point F, measure 1/3 of the pitch length along the main rope direction and mark it as G. Insert the remaining end A as the rope core into the main rope;

Step 4. Use the same method to make the eye ring at the other end, arrange it, and form an eye ring rope loop. Put the eye ring on the pin to directly test the rope.

Example 2:

Make an eyelet for an ultra-high molecular weight polyethylene tow rope with a diameter of 10mm, and connect the eyelet to the tow rope. The specific production steps are as follows:

Step 1, set the length of the finished tow rope to 6m, cut 7.5m of ultra-high molecular weight polyethylene fiber rope with a diameter of 10mm, and cut the two ends of the rope into a cone;

Step 2, mark A, B, and C from one end of the rope, where the spacing between A and B is 50 times the diameter of the rope, that is, 1250px, and the spacing between B and C is the length of the rope eyelet. The diameter of the tow rope part connected to the rope is 8mm, and the length of the eyelet spacing BC is 500px, so that the throat angle formed is within 10°;

Step 3, measure 1/3 of the pitch length in the direction of rope end A from end B and mark it as D, insert the main rope part from D and then pull it out until mark B and mark C are aligned. Overlap, the point on the main rope that overlaps with mark D is marked as E, and 1/3 of the pitch length is measured along the main rope direction at point E and marked as F. Insert and pull out end A from point F, and measure 1/3 of the pitch length along the main rope direction at point F and mark it as G. Insert the remaining end A as the rope core into the main rope;

Step 4, use the same method to make the eyelet at the other end;

Step 5, put the black sheath on the braided buckle and the core part of the eyelet rope loop at both ends, and sew the sheath on the rope with a sewing machine to fix it, and finish it to complete the sample.

Example 3:

Make an eye ring of an ultra-high molecular weight polyethylene lifting rope with a diameter of 12mm, and directly connect the lifting hook at the eye ring, where the diameter of the lifting hook connection is 10mm. The specific production steps are as follows:

Step 1, cut one end of the ultra-high molecular weight polyethylene fiber rope into a cone and tighten it with tape;

Step 2, mark A, B, and C from the conical end of the rope, where the spacing between A and B is 42 times the diameter of the rope, about 1250px, and the spacing between B and C is the length of the rope eye ring. The diameter of the hook connecting the rope eye ring is 10mm, and the length of the eye ring spacing BC is 750px, so that the throat angle formed is within 10°;

Step 3, put the hook on the rope, measure 1/3 of the pitch length from the B end in the direction of the rope end A and mark it as D, insert the main rope part from D and pull it out until it is marked B Coincident with mark C, the hook is installed at the eye of the rope. At this time, the point on the main rope that coincides with mark D is marked as E. At point E, measure 1/3 of the pitch length along the main rope direction and mark it as F. Insert and pull out end A from point F. Measure 1/3 of the pitch length along the main rope direction at point F and mark it as G. Insert the remaining end A as the rope core into the main rope;

Step 4. In order to enhance the wear resistance of the rope and the hook, the rope at the eye and the core needs to be coated and finished, and a dense protective cover is formed after drying.

Step 5. Cut the rope of the required length, fix the other section with black insulating tape, and package it. The finished product is finished.

Example 4:

Make an eye loop of an ultra-high molecular weight polyethylene mooring rope with a diameter of 20mm. In actual application, the eye of the rope is connected to the mooring column. The production steps are as follows:

Step 1, cut one end of the ultra-high molecular weight polyethylene fiber rope into a cone and tighten it with tape;

Step 2, mark A, B, and C from the conical end of the rope, where the spacing between A and B is 45 times the rope diameter, that is, 2250px, and the spacing between B and C is the length of the rope eye. The diameter of the mooring column will be relatively large, and the length of the eye spacing BC is 2500px, so that the throat angle formed is within 30°;

Step 3, starting from the B end, measure 1/3 of the pitch length in the direction of the rope end A and mark it as D, insert the main rope part from D and then pull it out until the mark B coincides with the mark C to form an eye loop. At this time, the main rope is aligned with the mark D. The overlapping point is marked as E, and 1/3 of the pitch length is measured along the main rope direction at point E and marked as F. The A end is inserted and pulled out from F, and 1/3 of the pitch length is measured along the main rope direction at point F and marked as G. The remaining A end is inserted into the main rope as the rope core;

Step 4, in order to enhance the wear resistance of the rope eye ring, the rope eye ring and the core need to be coated and finished, and a dense coating sheath is formed after drying.

Step 5, cut the rope of the required length, fix the other section with black tape, and package it to obtain the finished product.

Recent information